Machine features

Machine Features:Specially designed for fabric cutting. for fabric rolls, we have laser cutter with auto feeder. for printed fabrics and embroidery products, we have cutting machine with CCD visual positioning system. other functions can be customized.

Technical parameters

| Model |

LM-1610 With auto feeder |

LM-1810 With auto feeder |

LM-1625 With auto feeder |

LM-1825 With auto feeder |

| Laser type | CO2 glass laser tube, wavelength 10.6μm, water-cooled | |||

| Laser power | 100w, 130w, 150w | 130w , 150w, 180w | ||

| Working area | 1600x1000mm | 1800X1000mm | 1600x2500mm | 1800x2500mm |

| Engraving speed | 0-1000mm/sec | |||

| Cutting speed | 0-500mm/sec | |||

| Repeating location | ±0.01 | |||

| Transmission type | Belt transmission | |||

| Driving system | Stepper motor | |||

| Machine table | Blade table (alternative: honeycomb table) | |||

| Graphic format supported | *.plt, *.dst, *.dxf, *.bmp, *.dwg, *.ai, *.las, supporting AutoCAD and CorelDraw | |||

| Software supported | CorelDraw, AutoCAD | |||

| Control system | RuiDa DSP Off-line control system, laser power 0~100% adjustable | |||

| Minimum letter size | Chinese 2.0x2.0mm, English 1.0x1.0mm | |||

| Working voltage | Single phase 220V/50Hz (Optional: 220V/60Hz, 110V/60Hz) | |||

| Working condition | Temperature 0~45 Celsius; Humidity 5%~95% no condensation | |||

CO2 LASER WOKRING CAPACITY

| Material | Engrave | Cut | Material | Engrave | Cut |

| Wood | √ | √ | Pressboard | √ | √ |

| Acrylic | √ | √ | Rubber | √ | √ |

| Fabric | √ | √ | Wood Veneer | √ | √ |

| MDF | √ | √ | Plywood | √ | √ |

| Delrin | √ | √ | Plastic | √ | √ |

| Cloth | √ | √ | Cork | √ | √ |

| Leather | √ | √ | Corian | √ | |

| Glass | √ | Fiberglass | √ | √ | |

| Ceramic | √ | Tile | √ | ||

| Marble | √ | Anodized Aluminum | √ | ||

| Matte Board | √ | √ | Stainless Steel | ||

| Melamine | √ | √ | Brass | ||

| Paper | √ | √ | Titanium | ||

| Mylar | √ | √ | Bare Metals | ||

| Coated Metals | √ | Painted Metals | √ |

Please check with us if your material is not in the above list.

Video

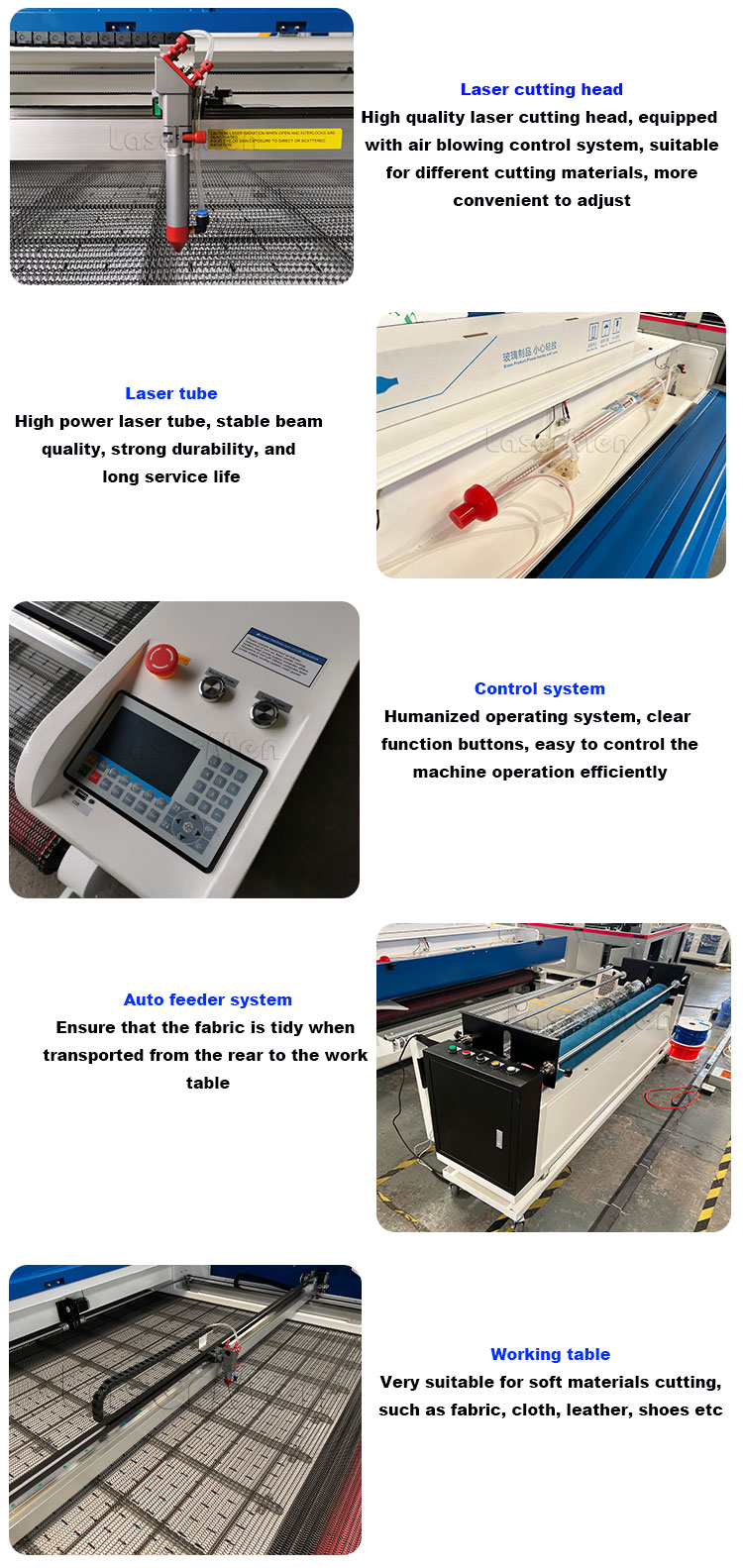

Machine details

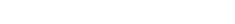

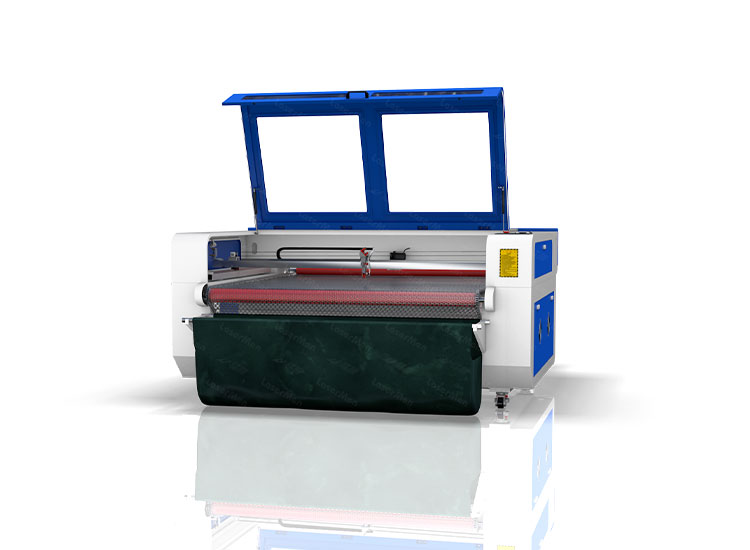

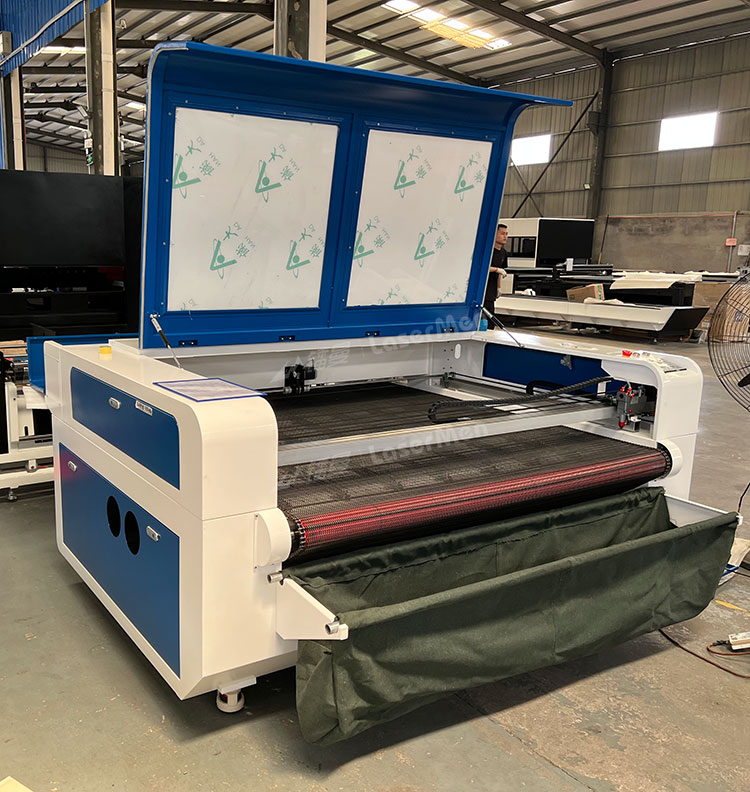

LaserMen fabric co2 laser cutting machine with auto feeding system:

LaserMen fabric co2 laser cutting machine has different typs for you to choose: 1610 laser machine with conveyor table, 1630 laser machine with auto feeder,1830 laser machine with auto feeder and ccd camera.

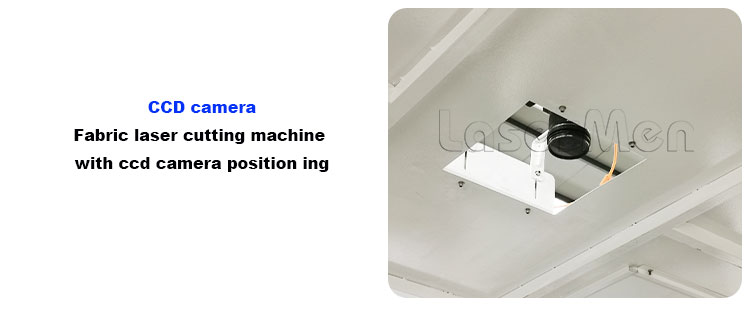

Auto feeding CCD camera fabric laser cutting machine

1. Automatic feeding system, more convenient and efficient for soft materials processing;

2. Auto calibration ensures fabric feeding in correct path and position.

3. Full size conveyor table carries fabric.

4. Wide angle CCD camera shoots the full table size, which is good choice for cutting embroidery and printed fabric products.

Small CCD camera, which is convenient and more efficient for cutting embroidery and printed fabric products.

5. CNC control system, RDC6445G control board, RDworks and RDvision software.

6. Suitable for mass production of large and medium-sized enterprises, as well satisfy the production needs of small enterprises and individual processors;

7. Machine working speed and laser power output can be adjusted in real time, greatly facilitating user’s operation;

8. High-performance laser engraving and cutting control system;

9. Applicable to various fabrics, smooth cutting edge without fins or burrs.

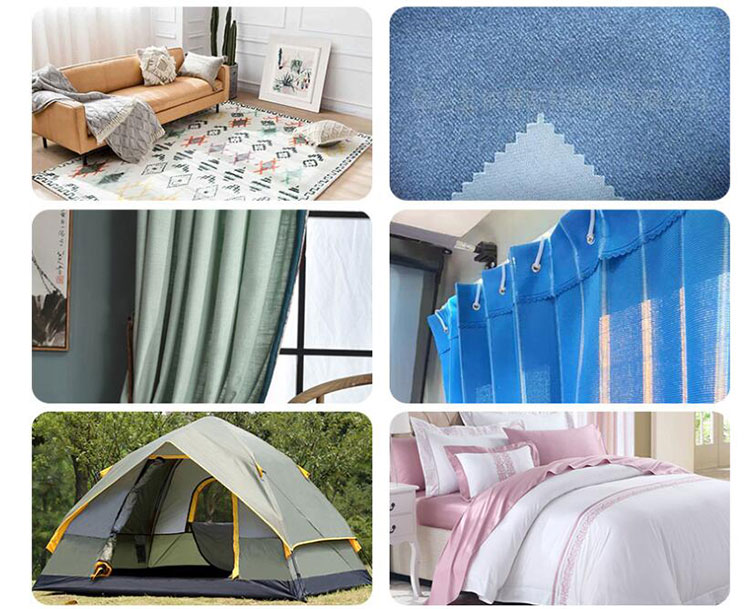

Machine Application

Applicable materials:Cotton cloth, linen cloth, leather, paper, chemical fiber and other textile and garment fabrics.

Application area:

Sofa release, curtain fabrics, carpets, outdoor tents, coated fabrics, tarpaulins, car interiors, home textiles and various textile products personalized customization, etc. Suitable for cutting various flexible soft materials, hollowing out, etc.